Conservation processes and techniques

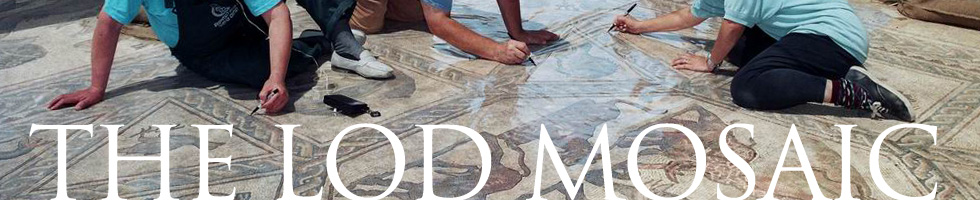

Conservation of the mosaic

After the lifting, part of the backing mortar was cleaned on the site, but still the weight of the mosaic was around 20000kg. The size and weight of the panels made their transportation a complicated task: the laboratory in the Rockefeller museum is not accessible to heavy trucks and so the mosaic panels with the wooden supports were transported manually to the storage area.

Each fragment was cleaned of residues from the backing mortar and the removed tesserae were glued back in the original places.

Two fully-adjustable platforms were built to permit the construction of the new supports and the rejoining of the mosaic.

Preparation of the mosaic for the application of new supports:

- A group of 8 panels (around 40sq. meters) were re-puzzled face down and the joins between panels were checked. Consequently the panels were separated in the same order and a frame was built around each fragment. The voids between the mosaic and the frames, and all the lacunae were filled with lime mortar to prevent the infiltration of epoxy resin to the surface.

- Application of sacrificial layer: this layer of lime based hydraulic mortar (hydraulic lime and stone powder in ratio 1:2) was applied directly on the back of the tesserae.

- Construction of the new supports: Aerolam panels supported by aluminum bars constructions with the dimensions and forms of every fragment were produced in the lab. To connect the Aerolam panels with the construction special inserts from the aerospace industry were used.

- Application of the new supports: every support was glued to the sacrificial layer using epoxy resin (Araldite 257 with perlite filler). The high of every fragment was controlled during the application of the supports.

- Cleaning of the facing: after the polymerization cycle of the epoxy resin was over the fragments were flipped again this time with the face up. The residues of the lime mortar used to protect the edges were cleaned very easy mechanically. Poultices of hot water were used to remove the fabric and the glue from the surface of the mosaic. Cleaning with soft plastic brushes and scalpels eliminated completely the glue residues from the surface.

- Cleaning of the mosaic surface: poultices of ammonium carbonate solution and paper powder were used combined with the use of pneumatic tools and scalpels.

- Rejoining of the mosaic: 100sq.meter concrete platform was used to recombine the fragments of the mosaic. This process includes checking of the levels and connections between fragments. A lot of precise and very fine cuts and adjustments are needed in order to achieve a perfect fit between all of the panels.

- Integration of the lacunae: the technique of discovered under painting will be used for the re-integration of the missing parts in the mosaic. The mosaic design will be recreated using impressions of tesserae in lime mortar and painting with watercolors of the main lines. The aim is to have the effect of missing tesserae, but exposed lime bed with the traces of synopia on it.

Consolidation of the glass tesserae:

1. In-situ treatment

- Salt extraction: poultices with de ionized water and paper powder (Arbocell 200).

- Consolidation with poly ethyl silicate RC 80 (Rhodia), application with small brushes until saturation.

2. Treatment in the conservation lab

- Back side: after the cleaning of the backing mortar consolidation with poly ethyl silicate RC 80 (Rhodia)

- Face: after the cleaning of the glue from the mosaic surface, additional consolidation is possible (with the same material)

Conservation: 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | Next page